What is black masterbatch and what are its features?

-

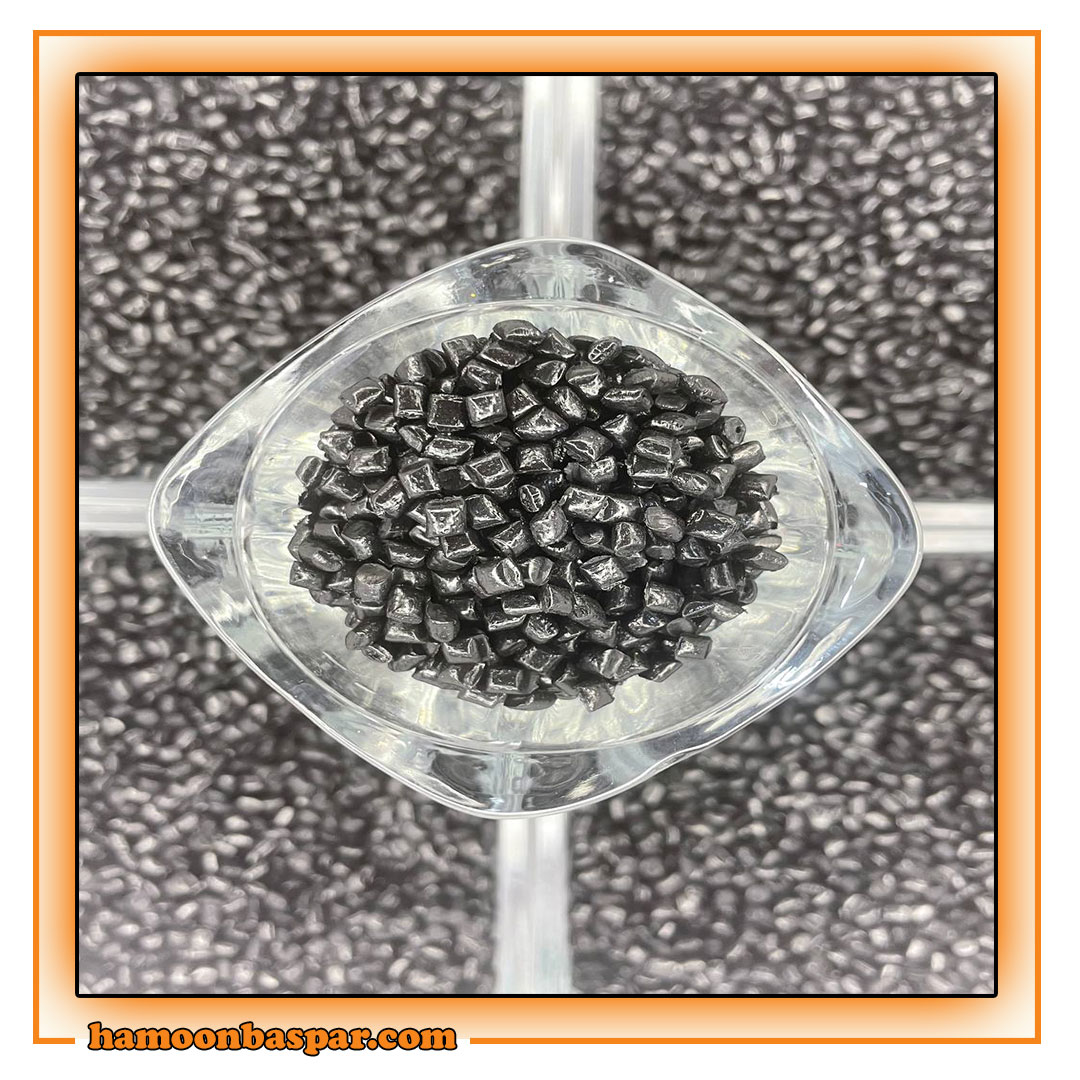

One of the boosters and additives that have many uses in today's world is مستربچ مشکی. Due to the issue that various needs in industries cannot be met only with produced polymer chains, additives are added to polymers to meet the needs of industries. In fact, these compounds are the same as the masterbatch. One of these popular compounds, in addition to the colored masterbatch, is the black masterbatch, which is one of the important properties of this compound. This feature in the black masterbatch has caused this compound to spread in the desired polymer. In the following, we discuss the ingredients of Black Masterbatch and its use.

What materials does the black masterbatch consist of?

In general, masterbatch is produced from a combination of carbon black and polymer.

For plastic industries, the use of plastic grade carbon black is allowed because the use of this carbon black does not change the properties of the polymer.polymer

According to the said material, we know that the needs of the industries cannot be solved only with polymers. Therefore, it is necessary to add certain compounds to polymers to strengthen their specific properties. In fact, polymer is the main base of masterbatch. Polystyrene, alkyd polymers, polyethylene, polypropylene, etc. are among the types of polymers.

additive

As mentioned, additives are added to polymers to strengthen or change them. Additives that strengthen the properties of polymers, fillers and pigments can be mentioned among the additives. Carbon black additive is allowed for polymers in black masterbatch.

Adapting agent

The mental concern of many producers is how to paint polymer compounds and additives. In order to get a special color by these compounds, it is necessary to spread and distribute a combination of color and additive, which is usually in molten form, in the base polymer along with the polymer compatible with the final product. It goes without saying that the equipment and devices have a great impact on the produced masterbatch.

Suggested study: Reasons for changing the price of masterbatch types

Characteristics and features of the equipment used in the production of black masterbatch

One of the important features of the equipment used in the production of high-quality masterbatch is the ability to create the right force for the mixture of existing compounds. Another feature of this equipment is the ability to control compounds, because the quality of polymers and additives at low temperatures will be low due to not mixing well, and at high temperatures, the stickiness and viscosity of the material will be lost, because at high temperatures, the polymer is in the form of melt and paste. comes out In this case, it is possible to break its main chains. When the polymer has a lot of adhesion, it is the best time to add additives to the black masterbatch. Because this time is very suitable for adding additives. It should be noted that in this case the material will also have good adhesion.

Application of black masterbatch

Today, black masterbatch has many uses in the industry. This colored masterbatch is used in Iranian industries for two reasons.

- Dyeing base polymers

- Reinforcement of polymers

Compositions made from this masterbatch are always black in color. Of course, black masterbatch is also used in the production of other products. These products include the following:

Pipes and fittings based on standards in different sizes

- Food containers

- Various plastic bags such as garbage bags

- Products created through plastic injection

- Various car parts

- Home Appliances

- Strong cardboard plastics and their use in various applications

Effective factors in the percentage of using black masterbatch

In general, masterbatch is used in compositions in the range of 0 to 50%. But in order to know how many percentages should be used for the exact composition of this product, we consider some factors:

- What is the quality of the additive used?

- What is the final concentration of the product?

- How thick is the production sheet?

- What are the required properties of the standard part?

Advantages of using black masterbatch

It is possible to increase the efficiency and profit of the final product by using masterbatch, because there is no need to spend energy, labor and money to create suitable compounds with the national polymer base despite these compounds. In addition, due to the preparation of the masterbatch in advance, the pigment and pigments are not scattered in that environment, and this will be very effective in maintaining the health of the workers. Another advantage of using black masterbatch is that masterbatch is evenly distributed in pigments and additives in the product. The color in this masterbatch is very durable and stable.

Because the devices and equipment used in the production of this masterbatch are of high quality. Materials and additives are combined in this equipment with the right force and at the right time. Another advantage of using this masterbatch is that due to the high compatibility of masterbatches produced with polymers, the melting process is done better and easier.

Comments